Process Mining and Lean Six Sigma

2 min read

The Process Mining module in T-K is a powerful tool to improve efficiency and eliminate waste in the context of lean six sigma. T-K ingests data from various sources and visually represents how a process is carried out, identifying bottlenecks, inefficiencies, and opportunities for improvement.

One of the key benefits of T-K is its ability to provide an objective view of a process rather than relying on subjective perceptions. This can be particularly useful in lean six sigma initiatives, where data-driven decision-making is emphasized. T-K can help identify areas for improvement that may not be immediately obvious.

Identifying Waste

One of the most common applications of process mining in lean six sigma is identifying waste, or non-value-added activities, in a process. By analyzing data on process flow, cycle times, and other factors, process mining can help identify unnecessary movements that could be streamlined.

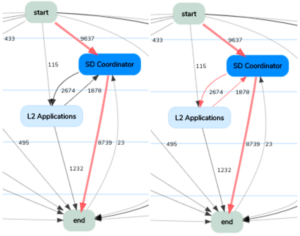

The accompanying image demonstrates how T-K compares paths with a cycle to those without to accomplish the same type of work. This comparison offers a directional insight into the extra time and human effort associated with the cycle.

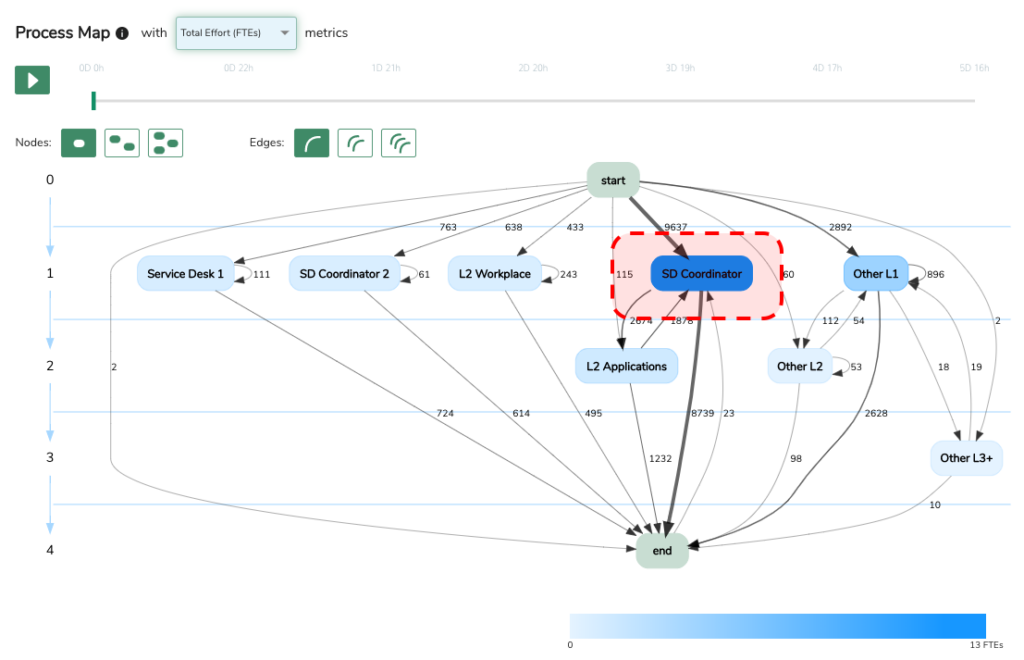

T-K’s Effort Model

T-K is also able to heatmap the nodes of the process map by various metrics. A notable example is the amount of human effort spent in each node. In the example below, the SD Coordinator requires the most human effort, needing 13 FTE of human dedication to fulfill that step.

As T-K quantifies effort, we can not only determine the amount of elapsed time wasted due to inefficient processes but also the extent of human effort wasted in the process!

These are examples of how T-K’s Process Mining module could shed light across the entire DMAIC model of Six Sigma.

Overall, T-K can be a valuable tool for any organization looking to improve efficiency and eliminate waste through lean six sigma initiatives. By providing a data-driven view of processes and identifying opportunities for improvement, process mining can help organizations significantly improve productivity and efficiency.

Time to Implement

Once the data is available and ingested by T-K, producing these dynamic maps based on the operational data takes a few seconds.

Let’s discuss doing a quick diagnostic together, loading real data from your organization into T-K, and demonstrating the business value add of our intelligence engine in your operation.