CKM Customer Journey: Fixing a Broken $100M+ Automation Program

5 min read

Large organizations are complex, often consisting of operations that evolved over several decades. Throughout this time, thousands of people come and go. While knowledge can be shared and maintained, the reason why things are the way they are is never quite clear. So, new hires look at these decade-old processes and generally seek to uphold them like sacred rituals. When new problems or technologies arise, leaders generally elect to add to what is existing, instead of stripping things down and questioning if components need to exist at all. Over time, this results in clunky processes and constantly growing work volumes that are just as bad for customer experience as they are for operational efficiency.

Despite this unfortunate, natural tendency for an operation to degrade in quality over time while becoming bloated with unnecessary work volumes and automation, it can be avoided with the right attitude and toolset. We recently sat down with one of the most talented digital transformation leaders we’ve had the pleasure of doing business with to discuss what his challenges looked like first-hand. Below we’ll review their experience as well as the ways in which CKM Analytix was able to support this customer in reaching their ambitious targets for operational efficiency.

The Wrong Data is Worse than No Data

The first day our customer walked into his new role at a major international IT services organization, he not only inherited thousands of complicated processes but even worse, a fully funded $100M+ automation program with a lot of momentum but little evidence of real results that justified its expense.

It was a big challenge for our customer, and still a common challenge for leaders today, just to evaluate the program’s effectiveness. This was mainly due to data limitation since the actual expenses a work group incurs is not a perfect function of what one sees in aggregate reporting. In other words, an automation of 10% of a group’s work rarely translates into a 10% savings. Despite this disconnect, tracking the total volume of work automated by the program was the closest the team had to measuring its success. So, when the program identified an opportunity to automate one thousand tickets in a new account, it was celebrated.

Of course, to someone managing the day-to-day operation, automating one thousand tickets sounds great; but remember from our introduction the tendency for leaders to add to an operation instead of questioning it and identifying potential redesigns and reduction in work. Our customer hypothesized that a lot of the existing automation was value-less, and that much of what was automated did not need to exist in the first place. This could explain the lack of bottom-line results but was a radical idea for those leading the program, and something they could never admit to themselves without proof. At this point, our customer knew he needed an unbiased and data-driven assessment of this program to truly understand what was going on, and that’s when he turned to CKM Analytix.

Put simply, CKM’s value proposition lies in our ability to build a comprehensive picture of operations by processing several different data sets and layering AI driven insights such as clusters of repetitive work and accurate predictions of total human effort. These measures give leaders better data to make better decisions, such as automating work only after exhausting all efforts to eliminate or redesign it. This ability proved invaluable to our customer, who not only needed to measure the effectiveness of existing automation, but also completely rethink how future investments were to be made.

Shedding the Dead Weight and Rebuilding the Body

To bridge the divide from raw data to meaningful recommendations, CKM has developed algorithms that are not simply analytically strong but segregate between what matters and what does not matter to its clients. As CKM put its technology to work, the data started to speak for itself. CKM’s tools were able to identify thousands of repetitive work items across dozens of accounts that could be completely eliminated, instead of automated or left unaddressed. Under the hood, this is achieved by leveraging contextual information embedded in existing data to cluster similar items and then analyze the repetitive nature of these groups. Those that are very cyclical with significant human effort, like transient capacity monitoring alerts might appear unimportant at first blush but make excellent candidates for root cause removal or automation. Repetitive work clusters that are not cyclical, like common follow-ups for incorrect or long-running resolutions, generally identify work volumes that represent symptoms or side effects of other broken processes that could be eliminated by process redesigns.

As data is generated in an organic way by multiple systems and people, continuous analyses provide a dynamic canvas to better understand what is natively visible to humans but also to identify unexpected patterns that shed more light on key interactions at an elemental level and between core components. This has allowed CKM to present its results in ways that can open the minds of senior managers and battle-scarred operators to solve their problems.

Providing this new operational view helped our customer completely reprioritize the efforts of the program, with the new priority being to clean up the operation. Nevertheless, while the objective was clear, the operation was enormous and segmented into dozens and dozens of different accounts and internal functional units. Success would not be possible without an organized effort. So, our customer led his team on a laser-focused mission to reduce as much work as possible, leveraging our data-driven AI-powered tools and technology wherever possible. While change was not always so obvious overnight, the results were significant.

Once the operation was thoroughly cleaned up, it made a lot of sense to automate what remained. The way that these automation investments were decided would change, however. This is because CKM’s tools provided better data that could enable better decisions that would ultimately result in much better bottom-line returns.

As we recall from the intro above, it is common for automation success to be measured in volumes, even though this doesn’t correlate perfectly to total human effort that can be eliminated. In reality, actual bottom-line automation success is measured by the net savings produced by the investment (i.e. elimination in expense) over its cost. So, to accurately assess the potential returns of a new investment, a fundamental understanding of human effort is essential. The CKM toolset and process also produces a ‘baseline model’ of existing work effort to allow the teams to agree on what needs to be optimized. However, this model also becomes a very effective method of tracking success and ensuring the corresponding costs are removed once optimizations are completed.

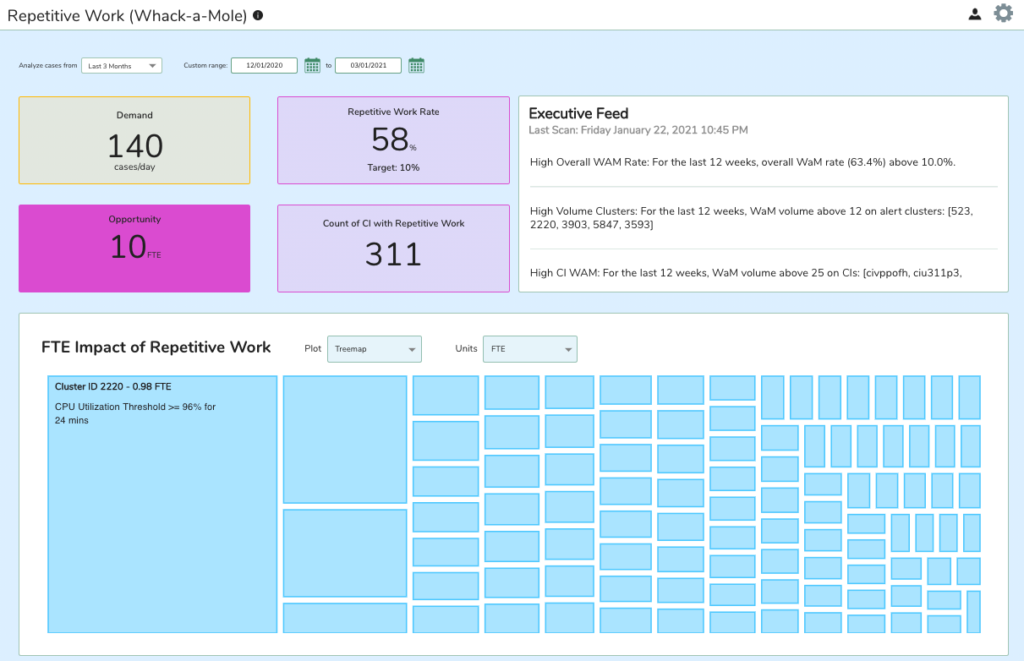

This is where CKM’s Effort Model is so powerful, as it quantifies the total human effort for every identified cluster of repetitive work. As we can see in the Figure 1 screenshot below, T-K demonstrates the total human effort, or full-time equivalent (FTE) units, for every cluster, so leaders of automation programs can prioritize automation based on where they can eliminate the most work (like the largest cluster below), not volume. Furthermore, with an accurate measure of FTE units saved, one can justify more costly investments. For our customer, this meant he could justify the additional $65M in investments he made by the nearly $700M in savings achievable in the first year alone. Two years after the beginning of this program and those investments continue to pay dividends – with a total savings figure now near $2B.

Figure 1: T-K Software Repetitive Work Module

To learn more about our effort model and its importance, check out this dedicated post.

Improving Legacy Operations with Better Data and Changing Hearts in the Process

Nothing changes if nothing changes, and our customer knew this. He and his team worked extremely hard to achieve the results mentioned above. Nevertheless, the new data-driven operational view CKM provided was fundamental in turning things around and enabling our customer with the right toolset and data to meet his ambitious goals for operational efficiency. Moreover, it helped him get buy-in from his colleagues and confront a work culture that was stuck in the past. Unsurprisingly, a near 10x return on investment was enough to convince any non-believers of the value in using better tools and better data to question existing processes.

Another consequence of this effort was a cultural change within the Operations team – both at the managerial and hands-on levels. The use of irrefutable data, making simple observations from complex environments changed the way people spoke about their job and allowed people to focus on ‘removing errors’, ‘eliminating waste’, and ‘improving quality’ vs. more traditional headcount and cost reduction initiatives. The conversation became less about the age-old IT mantra of ‘do more work with less people’ vs. ‘have fewer people conducting valueless work’.

This change in attitude and usage of tools didn’t just change the existing operation, but completely revitalized the outlook for the entire company. This in turn set all of its customers on track to better service while simultaneously improving efficiency – the dream for any delivery executive.